Continuous maintenance can extend the life of a water well while also increasing the yield.

As an analogy – think of spraying off a dirty screen. By opening up the original holes and cleansing the gravel around that screen, water can flow at either the original velocity or at times, an increased level.

Mechanical and Air-Surging

After the screen and casing are set, the well is then developed by a surging process with a double disc tool and augmented with compressed air. This technique can remove much fine material from the screen and formation area.

This activity is then coupled with chemical additives that help to break down clays and fines that prove resistant to removal and greatly enhances the mechanical efficiency of the well.

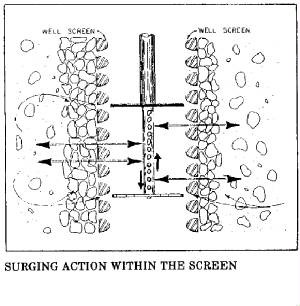

Figure 1.14 shows is are surging process for well cleaning.

Figure 1.14 shows is are surging process for well cleaning.

Over-Pumping and Backwashing

Pumping a well at a higher rate than it was originally designed is one of the easiest methods of removing fine materials from the water-bearing formation. When coupled with other development procedures, over- pumping can stabilize the aquifer.

Back washing procedures involve the intermittent reversal of the flow of water into a well. The turbulence created by alternately pumping the well and allowing the water in the pipe to re-enter the aquifer assists the development procedure.

High Velocity Jetting

One of the most effective methods of well development involves the use of water jetting at high velocity onto and through the screen. The forceful action of the jets working out through the screen Opening agitates and rearranges the formation surrounding the screen. This method also may correct the damage to the formation resulting from drilling.

Disinfecting wells

After installing a gravel pack, a concrete sanitary seal is placed in the upper portion of the well. This is to insure that no contamination can enter the well from above.

The final step in well completion is a thorough disinfection of the well to kill any bacteria that might be present. To do this, a variety of chemicals may be used, all of which are various compounds of chlorine. The effectiveness of disinfection is checked after treatment to insure a safe water supply.